Finishings

-

see more close

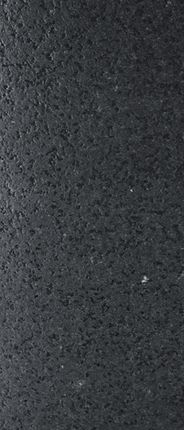

see more closeSplit-Face

It is done manually from the impacts of a metal tool on the stone, so that it breaks irregularly. Used as an ornamental finish to walls and exterior walls. For split-face surfaces, a thickness of at least 5cm thick is required, since part of it will be broken with the tools, leaving the material only 3cm thick.